×

Regional Sales Manager Request

Please fill out the form below to contact Beckett directly and we’ll get back to you within 24 hours.

The Beckett CG4 gas burner’s design uses technically advanced components, such as Beckett’s GeniSys® burner control and Powerlight igniter to meet increased demand for improved performance in high efficiency appliances and modern well insulated homes. The CG4 is also a certified conversion burner that can be used for replacing an existing oil burner when installations are converted to gas.

Our CG4 series chassis coupled with a welded insertion make a perfect match to your appliance. Performance-enhancing combustion technology utilizing proven fixed-head burner design.

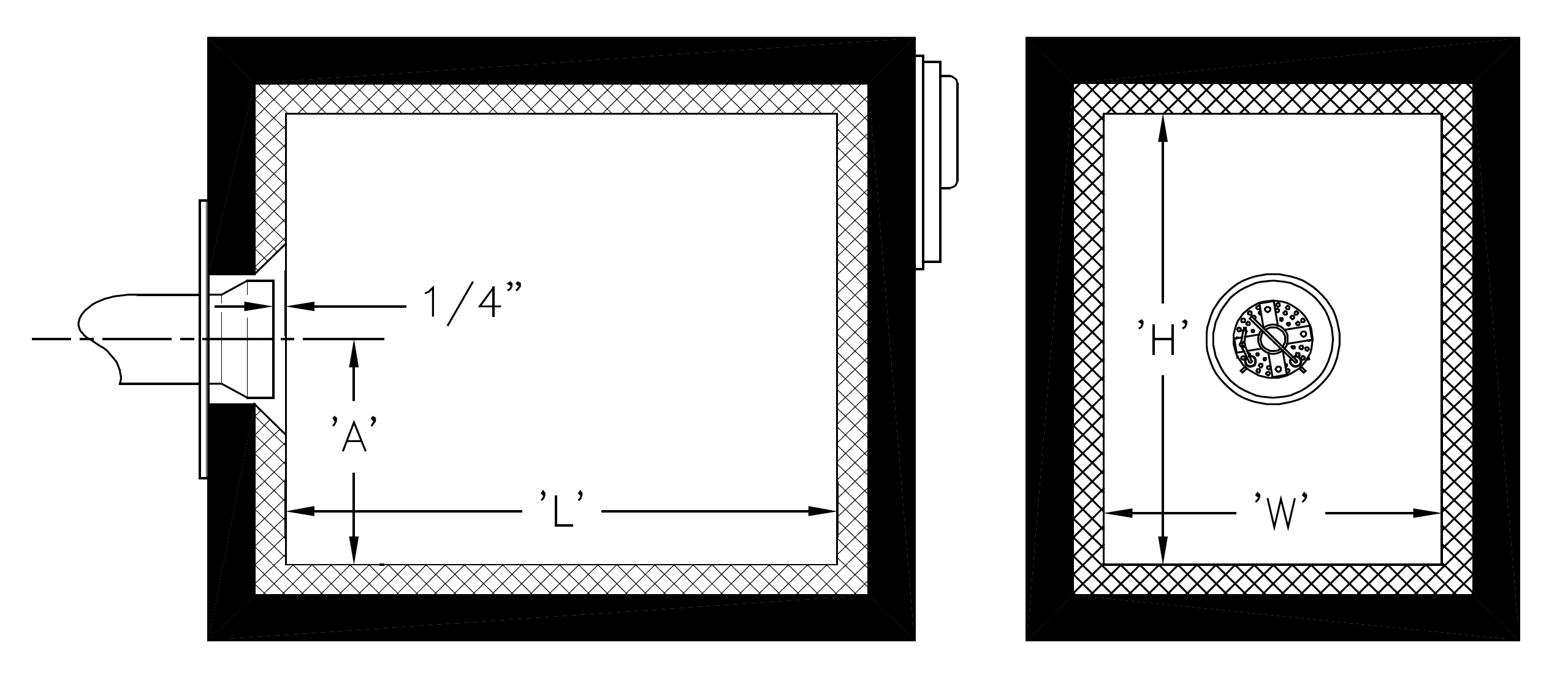

| Minimum Inside Dimensions (inches) | |||||

| Firing Rate MBH | Rectangular | Horizontal Cylinder I. D. |

Length ‘L’ | Floor to Tube ‘A’ | |

| Width ‘W’ | Height ‘H’ | ||||

| 80 | 8 | 8 | 9 | 13 | 4 |

| 105 | 9 | 9 | 10 | 13.5 | 4.5 |

| 140 | 10.5 | 10.5 | 12 | 14 | 5.3 |

| 175 | 11.5 | 11.5 | 13 | 14.5 | 5.8 |

| 210 | 13 | 13 | 14.5 | 15 | 6.5 |

| 250 | 15 | 15 | 16 | 16 | 7.5 |

Input Firing Range*: 80,000 – 250,000 BTU/hr

Firing Mode: On-Off Only

Fuel:

Required Input Gas Supply Pressure:

Input Voltage**: 120 Vac + 10% / -15%; 60 Hz Input

Input Current: 2.75 A (Run); 12.0 ALR

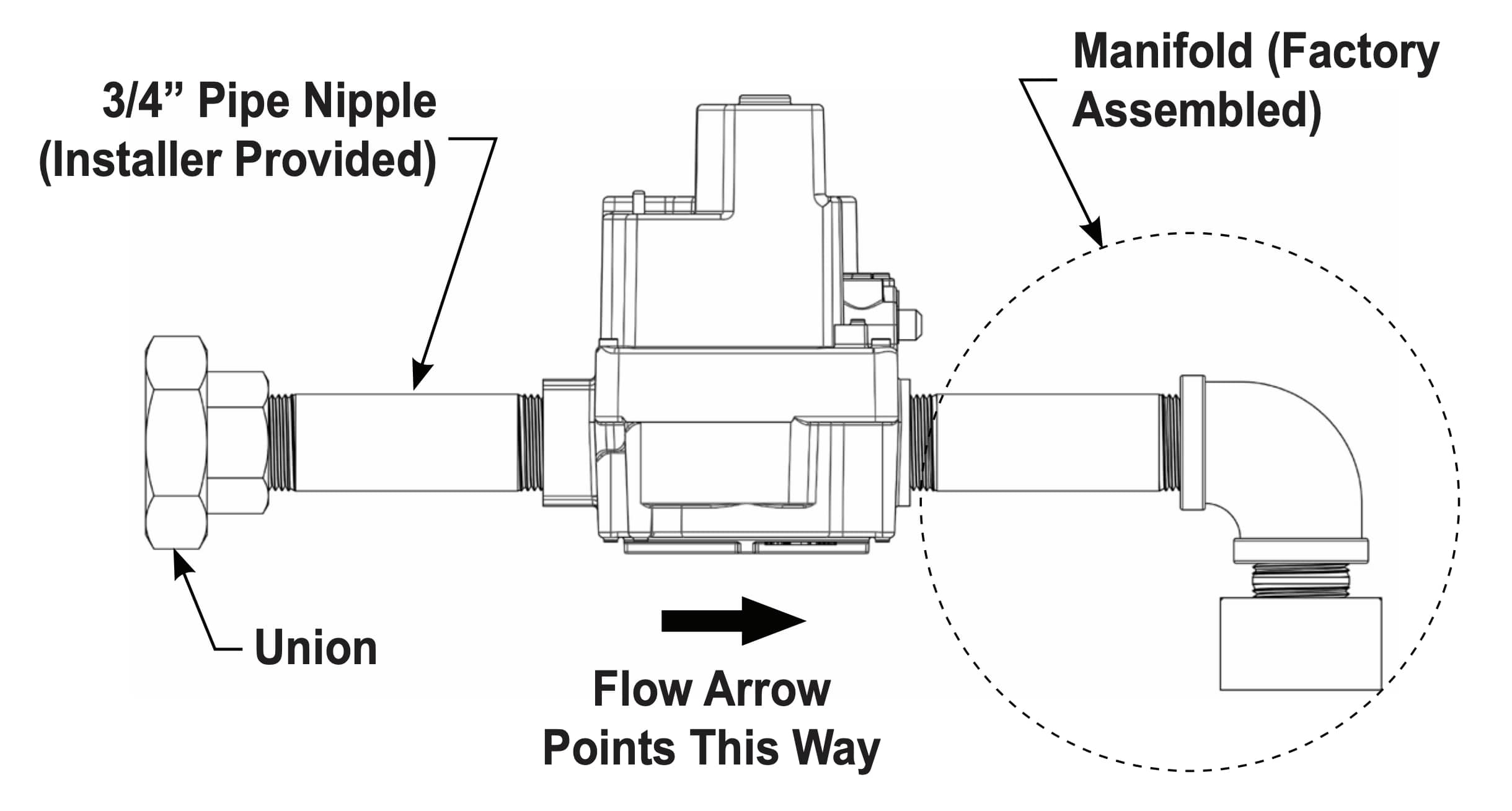

Gas Valve: 24 Vac Dual Seat with integral regulator set to 3.5” WC for both natural gas and LP

Burner Control: Beckett 7590C Direct Ignition

Flame Detection: Flame Rectification

Igniter: Beckett 7474001 Gas Igniter

Motor: 120V PSC 1/7 HP, 3,450 RPM

Combustion Air Proving: Differential Pressure Switch

Weight: 55 lbs.

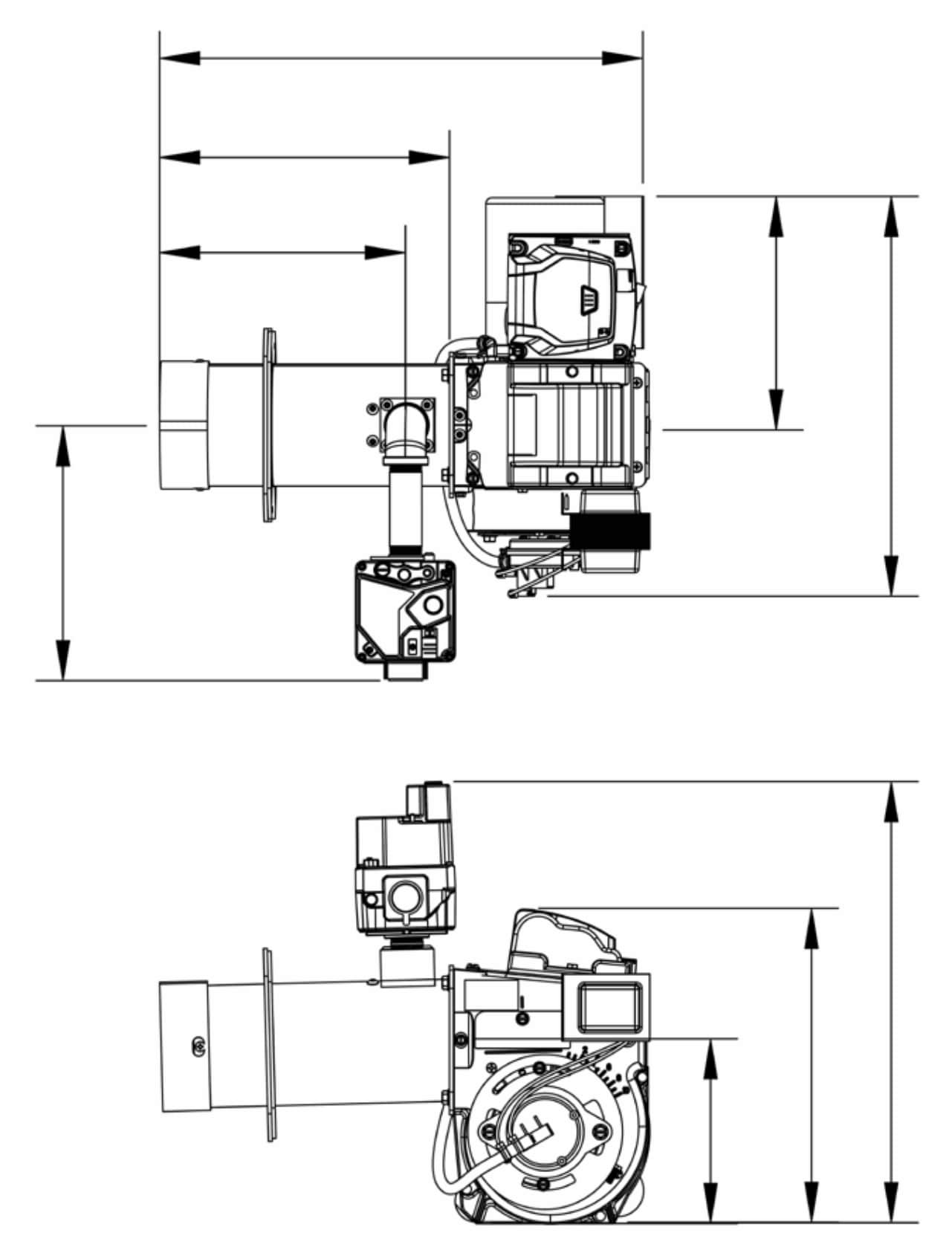

Mounting Orientation: Up to 90° from upright with motor shaft horizontal

Dimensions: 10.3″ x 13.1” x 15.8”

Air Tube Diameter: 4″

Acceptable Ambient Temperature Range: -40˚F to 150˚F

Acceptable Ambient Humidity: 5% – 95% RH non-condensing

* For altitudes higher than 2,000 feet, derate the burner capacity 4% for each 1,000 feet above sea level.

** This burner is not approved for use in 50 Hz applications.

| Firing Rate (BTU/Hr.) 1 |

Fuel Orifices | Air Tube Components 4 | Chassis Components 5 |

Initial Settings 6 |

|||||

| Natural Gas Orifice Diameter (inches) 2 |

LP Orifice Diameter (inches) 3 |

Burner Head | Nozzle P/N Suffix | Static Plate | Baffle | Band | Shutter | Band | |

| 80000 | 0.219 | 0.166 | F3G | 1 | 32910-001 | 5880 | Blank | 2½ | Blank |

| 90000 | 0.234 | 0.177 | F3G | 1 | 32910-001 | 5880 | Blank | 4 | Blank |

| 100000 | 0.25 | 0.189 | F3G | 1 | 32910-001 | 5880 | Blank | 5½ | Blank |

| 110000 | 0.277 | 0.206 | F3G | 1 | 32910-001 | 5880 | Blank | 7½ | Blank |

| 120000 | 0.316 | 0.219 | F3G | 1 | 32910-001 | 5880 | 4-slot | 9 | 0 |

| 130000 | 0.364 | 0.234 | F3G | 1 | 32910-001 | N/A | 4-slot | 5½ | 0 |

| 140000 | N/A | 0.242 | F3G | 1 | 32910-001 | N/A | 4-slot | 7½ | 0 |

| 130000 | 0.281 | 0.217 | F4G | 2 | 32910-001 | 5880 | 4-slot | 8 | 0 |

| 145000 | 0.316 | 0.234 | F4G | 2 | 32910-001 | 5880 | 4-slot | 10 | 0 |

| 160000 | 0.348 | 0.246 | F4G | 2 | 32910-001 | N/A | 4-slot | 6½ | 0 |

| 175000 | 0.406 | 0.261 | F4G | 2 | 32910-001 | N/A | 4-slot | 8½ | 0 |

| 190000 | N/A | 0.281 | F4G | 2 | 32910-001 | N/A | 4-slot | 10 | 0 |

| 180000 | 0.332 | 0.246 | F6G | 3 | N/A | N/A | 4-slot | 5½ | 0 |

| 190000 | 0.354 | 0.256 | F6G | 3 | N/A | N/A | 4-slot | 7 | 0 |

| 205000 | 0.377 | 0.266 | F6G | 3 | N/A | N/A | 4-slot | 8½ | 0 |

| 220000 | 0.422 | 0.281 | F6G | 3 | N/A | N/A | 4-slot | 10 | 0 |

| 235000 | 0.484 | 0.295 | F6G | 3 | N/A | N/A | 4-slot | 10 | 2 |

| 250000 | N/A | 0.312 | F6G | 3 | N/A | N/A | 4-slot | 10 | 4 |

1. Firing rates are based on a 3.5″ WC manifold gas pressure and use of the appropriate orifice for the fuel being fired.

2. Air tube assemblies are provided with a full selection of the natural gas orifices appropriate to the burner head.

3. LP orifices are provided in kits containing all the LP orifices for the burner head size. Kit P/N 52309-004 is for use with the F3G head, 52309-005 is for the F4G and 52309-006 is for the F6G. The installer is responsible for selecting and installing the appropriate orifice for the applications.

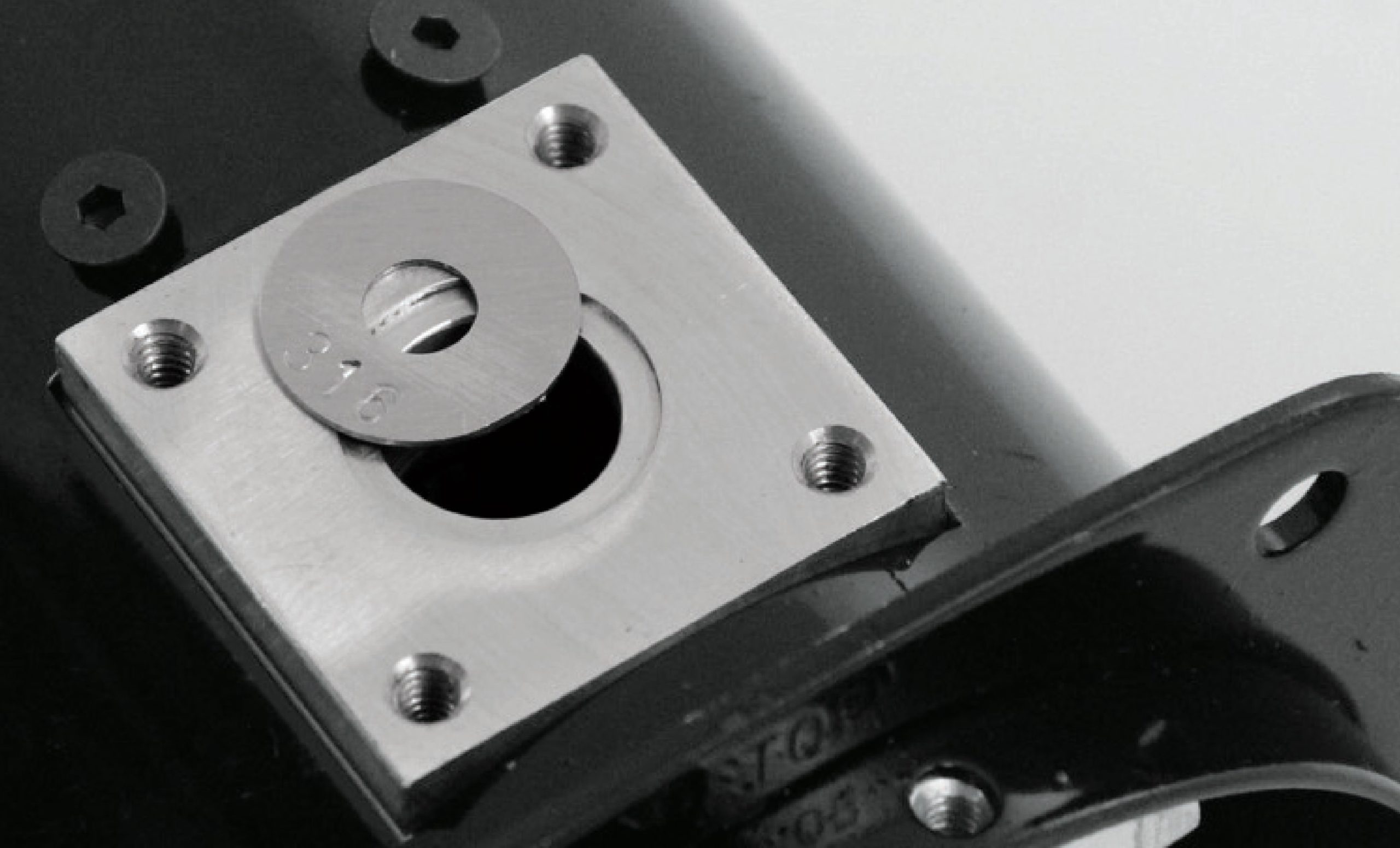

4 .Burner heads and nozzles are identified with the markings shown to assure the use of compatible combinations.

5. Burner chassis are built for the highest rate configuration. The installer is responsible to add the baffle and/or change the band as required for the application.

6. Initial settings are intended for use only as a starting point for burner adjustments. They cannot make provision for all installation possibilities. It is important that you adjust your burner to your installation requirements using properly calibrated flue gas analysis instruments.

Our heavy duty 16-gauge steel control boxes can be mounted on any of our commercial CF & CG Series burners. They come in 2 convenient sizes (12″ x 12″, 16″ x 12″) according to your burner needs. We have a variety of light indicators, voltage configurations, and other options to chose from.

Please note, all warranty claims must be initiated through an authorized Beckett supplier/distributor. Distribution policies will not allow Beckett to directly handle warranty claims with installers and/or consumers.

Informative and technical training resources from the leading experts in the heating industry

Have questions about our products? Looking for a solution to address a particular application? Looking to improve the overall productivity and profitability of your operation? Please don’t hesitate to reach out or schedule a no obligation, 1-on-1 consultation with a Beckett Technical Specialist — we’d love to help.

Beckett solutions are available through our network of Distributors, Independent Representatives, and Export Representatives all around the world.