Beckett Tigerloop® Oil Deaerators

R.W. Beckett’s oil deaerators were created with customer satisfaction and efficiency in mind. With over 30 years of fine-tuning, the Tigerloop® is the most advanced oil deaerator in the world.

With its unmatched performance, Tigerloop® can handle capacities up to 50 GPH and is compatible with different heating fuels, depending on the model. The standard model is compatible with #1 and #2 heating oil and B5 Bioheat, while the Bio model accepts biofuel blends up to B100. Catering to many needs, our oil deaerator is also a safe, economical, and environmentally friendly choice for all supply systems.

Up to 50 GPH

Fuel Types

#1 and #2 Heating Oil | B5 Bioheat | BioFuel to B100

Reduces air in system up to 95%

Applications

Residential Heating | Commercial Heating / Steam | Heated Pressure Washing | Agriculture / Greenhouse | Construction | Food Processing

The Advantages of Tigerloop® Oil Deaeration

Tigerloop Oil Deaerator eliminates many common oil heating problems which prevent a burner from operating at peak performance by removing air from the system, delivering foam-free fuel to the nozzle, and reducing issues caused by cold fuel — benefits which ultimately provide for cleaner, maximized combustion.

The Tigerloop Oil Deaerator improves the efficiency and extends the life of your oil heating systems. The Tigerloop combines the benefits of a single pipe system with a two pipe system. With a Tigerloop installed, you need only to transport oil at the nozzle firing rate (i.e. 1 gph). This allows you to use one small line from the tank to the Tigerloop, whereas with a 2 pipe installation you have to provision 2 large diameter lines that will handle oil traffic at approximately 20 gph in both directions.

Closed accordion

Extends Filter Element Life

By filtering less oil, typically around 1 gph vs. 20 gph, you dramatically extend filter life.

Conditions Oil for Cleaner Combustion

With Tigerloop, the oil travels slowly into the house (at around 1 gph) and loops through the Tigerloop and pump multiple times, picking up heat before it is fired. Contrast this to a 2 pipe system where cold oil enters the house rapidly (20 gph) and then is immediately sent back outside into the cold tank again (this also stirs up sediment in the tank, which can clog nozzles and filters).

Eliminates Potential Leak Hazard

Without the pressurized return line that is constantly pumping oil back to the tank, Tigerloop dramatically reduces the risk of leaks.

Closed Accordion

Reduces Running Vacuum

Vacuum pulls vapor right out of the oil even in an “air tight” system. Less vacuum means less air which means clear, foam-free oil at the nozzle. Installing a Tigerloop cuts the flow rate down below the firing rate of the system, typically 1 gph, dropping vacuum and improving burner efficiency while putting less strain on your oil pump and motor.

Reduces Air Up to 95%

With a 2 pipe system, all of the air and fuel in the line flows through the pump, flows by (or out) the nozzle, and then gets returned all the way back to the tank. The Tigerloop de-aerates the returning fuel before sending it back to the pump — reducing air by up to 95% and improving efficiency. The flame will sputter less, the burner will fire cleaner and prevent deposits on the heat exchanger which can build-up and interfere with the absorption of heat.

Reduce Lockouts, Flameouts, and Sputters

In a single pipe system, all air in the line has to go out the nozzle. So installing a Tigerloop will dramatically improve efficiency.

How Tigerloop® Works

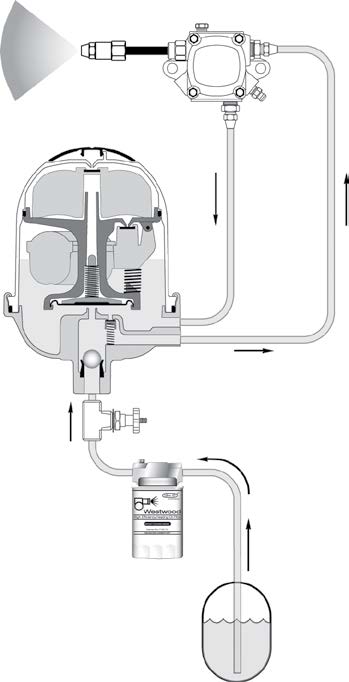

Having a Tigerloop is better than either a single pipe system or a 2 pipe system. Here’s how it works:

Tigerloop pulls oil through a check valve (inside the Tigerloop) and then through the pump. The pump gives the nozzle what it needs (i.e. 1 gph) and then sends the excess 19 gph back to the Tigerloop to be de-aerated. As oil rises in the Tigerloop, air escapes from the top vent until a float lifts and seals the vent. When the vent seals, the Tigerloop builds pressure (about 1/3 psi). The pressure opens a valve sending de-aerated oil back to the pump, creating the loop. If any air reaches the Tigerloop, the float drops, the vent opens, and the air is removed. The float rises again sealing the Tigerloop.

Featured Product

- Reduces air in the system by up to 95%

- Reduces running vacuum

- Significantly reduces potential leak hazard

- Conditions oil for cleaner combustion

- Reduces lockouts, flameouts, and sputters

- Extends filter element life

- Maximum nozzle capacity of 29.0 GPH

- Temperature range of 20˚F to 105˚F

Beckett Tigerloop Oil Deaerators

Learn more about Beckett Products

View by Brand

Beckett Training is Now Online

Informative and technical training resources from the leading experts in the heating industry

We're Here to Help!

Have questions about our products? Looking for a solution to address a particular application? Looking to improve the overall productivity and profitability of your operation? Please don’t hesitate to reach out or schedule a no obligation, 1-on-1 consultation with a Beckett Technical Specialist — we’d love to help.

Where to Buy

Beckett solutions are available through our network of Distributors, Independent Representatives, and Export Representatives all around the world.