The goal of every oil burner serviceman is to assure dependable, on-going heat for the customer. This is why filtration of the oil supply makes sense. Look inside the fuel oil pump, or a burner nozzle and you’ll see that filters are included by the manufacturers of these components. They know that filters not only assure burner dependability, but can extend the useful life of these components by keeping them clean.

The same kind of preventive thinking has led many to recommend that the burner be protected by dual filtration of the fuel oil supplied.

What is Dual Filtration?

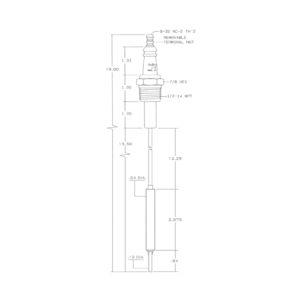

Dual filtration is the use of two filters on the fuel supply line. These are known as the primary and the secondary filters. The primary filter is located close to the fuel supply tank to protect the fuel lines from contaminant accumulation and to give maximum useful life to the secondary filter. The secondary filter is located on the fuel supply line just before it reaches the burner. It is not uncommon for this filter to be mounted to the fuel unit inlet port by way of a short pipe nipple.

How Fine Must Filtration Be?

A filter fine enough to stop any particle larger than the narrowest passage in the typical nozzle might sound ideal. For instance, in a .65 nozzle, the slots have a width of 150 microns. So you would think that a filter that stops anything wider than 150 microns would do the job. However, because of agglutination, the filter must stop particles down to 50 microns.

Agglutination happens when particles jumble together and form a mass larger than their individual selves. This can jam a slot in a nozzle, as well as cause an erratic or irregular spray pattern.

A rating of less than 50 microns is best for protecting the burner system, both at the primary and the secondary filtration points. Normally, with this protection, anything that passes through the filters should be able to pass through the fuel pump and the nozzle.

Conclusion

Dual filtration in the fuel supply helps to prevent no-heat calls by keeping burner components clean and functional. The filter cartridge in each of the filter units should last from the annual checkup to the next scheduled annual checkup. At that time, the burner nozzle should be changed along with the filters. After completing your annual tune-up, make sure the filter is disposed of according to EPA regulations.