Not all nozzles are exactly alike. There are variations from one manufacturer to another. Conversion charts are good guides, but they do not always take into account the variances.

The problem is that standards do not exist to accurately define hollow and solid. Many methods have been proposed, but none perfected.

This bulletin will provide you with several points to keep in mind when making a nozzle selection for a burner retrofit job.

THIS TASK HAS BEEN DONE FOR YOU IN APPLIANCE/BURNER PACKAGES.

How Does It Work?

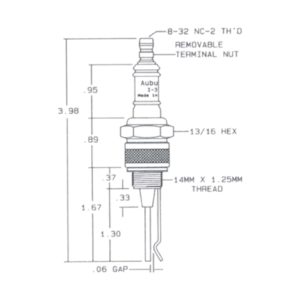

Let’s look at how a nozzle works, and then consider what we expect a nozzle to do. Energy is required to break up the oil into droplets. The energy is supplied by the fuel unit delivering oil to the nozzle from 100-150 PSIG for most residential applications and up to 300 PSIG for commercial applications. The nozzle, through the swirl slots, swirl chamber and orifice converts the energy from pressure to velocity. Approximately half of the pressure is converted or dropped across the swirl slots and chamber.

At this point, as their name implies, the swirl slots cause the oil to swirl in the swirl chamber. The swirling oil is forced toward the orifice, causing the oil to form a hollow tube. As this hollow tube exits the orifice, a cone shaped film of oil develops. The film quickly separates into ligaments (1) which stretch to their breaking point, thus forming the droplets.

Refer to our February 15, 1985, technical bulletin, where the affects of viscosity on flow rate and droplet size were discussed. If you suspect that viscosity is causing a problem with combustion or light-off, do not hesitate to install a smaller nozzle and increase the pump pressure.

Expectations

A nozzle is expected to deliver properly atomized fuel at a precise rate over a broad range of conditions. The fuel may be 40-50°F, the nozzle may operate at temperatures up to 250°F and the off cycle soak temperature may climb to nearly 300°F in some appliances. In spite of the adverse conditions, we expect the nozzle to deliver properly atomized fuel at the correct rate, pattern and angle.

We must help the nozzle do its job. First, make sure that the fuel supplied to it is clean and air free! Make sure the pump pressure is set properly. For domestic applications it may be 100 PSIG to 150 PSIG. When installing the nozzle, use extreme care to protect the nozzle orifice and strainer. If the orifice gets dirt in it or becomes scratched, it will not function properly.

Inspect the nozzle adapter before installing the nozzle. If there are deep grooves cut into it from previous nozzles, replace it. Those grooves or a scratched surface are a potential source for a leak.

Do not over torque the nozzle when tightening. Over torquing will cut grooves into the adapter and cause leaks when the next nozzle is installed.

Hollow, Solid, All Purpose?

Due to the lack of standards to define the qualities that we give a nozzle, it is difficult to even generalize about their use and application. In the laboratory many of the tests performed are conducted to select the proper nozzle. With any given combustion system, nozzle selection will be determined by the environment into which the burner is being placed.

Due to the lack of standards to define the qualities that we give a nozzle, it is difficult to even generalize about their use and application. In the laboratory many of the tests performed are conducted to select the proper nozzle. With any given combustion system, nozzle selection will be determined by the environment into which the burner is being placed.

There are many choices available for a nozzle, it is best to follow the appliance manufacturer’s recommendations. They have, in conjunction with the burner manufacturer, conducted many tests to determine what works best. What works best is that combination of components, including the nozzle, that meets the performance requirements of the appliance manufacturer, and results in smooth starts, runs and stops. At times this is a compromise. To obtain the proper light-off and run that is required for long-term cleanliness, some performance may have to be sacrificed. The nozzle that provides the highest level of performance in terms of CO₂ and smoke is not always the nozzle that provides the smoothest light-off and run. For those reasons we encourage following the manufacturer’s recommendations.

Some Guidelines

With our F series heads, we generally find that from .5 to 1.5 GPH, an 80° hollow works best. For all of the reasons noted above, however, that is not a hard and fast rule. There are some O.E.M. applications that call for solid nozzles in this range.

From one gallon and up, our typical application is running with an 80° solid. Yes, there is an overlap between a gallon and a gallon and a half. The only sure way to know which nozzle provides the best performance is to put them in and run the combustion tests. That is the way the correct nozzle is determined in the laboratory.

Here are some other factors. The burner combustion system is a factor as is the chamber size and shape. Over the years, correlations have been drawn between “burner air patterns” and nozzle and chamber configuration and nozzle pattern. With today’s flame retention burner, these generalities no longer hold true.

The circulation or recirculation patterns within the combustion zone and the design of the burner combustion parts will have a much greater influence than any of the other factors involved. The flow of gases within the combustion zone is extremely difficult to study without disturbing or upsetting the pattern. Therefore, when you must install the nozzle, test it with instruments, listen to it and look at the flame for the best performance possible.

Nozzle Sizing

Much information is available regarding the selection of the proper nozzle size in a retrofit application. We cannot cover it all here. Instead, the sources of that information are listed below. Guidelines for combustion chamber size for a given firing rate are provided by the burner manufacturers for retrofit applications. This information is found in the installation instructions manual. Remember, the proper nozzle size has already been selected for you in the case of a package unit.

Conclusion

When considering proper nozzle selection, remember these points:

- Always use the appliance manufacturer’s nozzle specifications.

- Follow the burner manufacturer’s recommendations when retrofitting a new burner to an old appliance.

- You must set-up the combustion with properly maintained test instruments. Smoke, CO₂, or O₂, drafts and pump pressure.

- Once the CO₂ has been determined at a trace of smoke, add enough extra air to reduce the CO₂ one and one-half percent.

INFORMATION SOURCES

Nozzle Sizing

“Professional Serviceman’s Guide to Oil Heat Savings,”

R.W. Beckett Corporation, P.O. Box 1289, Elyria, OH 44036

“Heat Loss Calculation Guide,” The Hydronics Institute,

35 Russo Place, Berkeley Heights, NJ 07922

“Cooling & Heating Load Calculation Manual,” American Society of Heating, Refrigeration and Air Conditioning Engineering, Inc. (ASHRAE),

1791 Tullie Circle, N.E., Atlanta, GA 30329

How Does It Work?

“A Total Look at Oil Burner Nozzles,” Delavan Manufacturing,

West Des Moines, IA 50265

FOOTNOTE

(1) Delavan Manufacturing, Spray Droplet Technology, ©1973