Heating appliance soot-up can be prevented if you know the causes. In this era of increased appliance efficiency, the service industry must stay abreast of new advances and the new requirements that must be met.

Appliances are more compact and streamlined. The emphasis is on AFUE ratings and on properly matching the firing rate to the heat loss of the building. Consequently, the reduced firing inputs and more efficient equipment usually result in lower stack temperatures and less volumes of heated gases going up the chimney. This necessitates some adjustments in our approach and installation procedures. You must consider the whole system from a new prospective.

Chimneys and Draft

In our industry, draft is the slight suction that exists inside the appliance and flue system. Natural draft is actually thermal draft. It occurs when gases that are heated expand, so that a given volume of hot gas will weigh less than an equal volume of the same gas at a cool temperature. Since hot combustion gases weigh less per volume than room air or outdoor air, they tend to rise. The rising of these gases is contained and increased by enclosing the gases in a tall chimney. The suction, or draft, is then created throughout this column of hot gases.

Therefore, a massive chimney on a cold, or exposed outside wall may have produced adequate draft when it was fired with a higher input and greater volumes of heated gases. With reduced input and volume, the draft may be severely affected. In one instance our research showed a new chimney of adequate sizing produced only -.035″ W.C. after 30 minutes of continuous firing at 13.0% CO₂. Outside wall chimneys take longer to heat up and can have .00″ W.C. draft at burner start-up. You may have to consider a special alloy chimney flue liner with insulation around it and a stabilizing draft cap or even a draft inducing fan in severe cases.

The method chosen must be compatible with the chimney design and should also address potential condensation and erosion problems within the masonry structure. This has to be taken into account BEFORE the installation takes place. In such cases, the modern high-static pressure flame retention burners can help greatly. However, they are not a cure-all for inadequate draft problems.

This becomes obvious when a conventional appliance is firing with slightly positive or over-fire pressure. It was not designed for this, therefore, combustion products are forced into the surrounding area through leakage paths around viewdoors, flanges, and even flue collector boxes. Adequate draft must be provided to remove exhaust gases effectively to the outside.

Burner Adjustments

Because draft may not be adequate at cold start-up, the burner air adjustment should be set accordingly. Here is what we recommend:

With the draft at a low setting over-fire (-.01″ W.C.), or that specified by the manufacturer, adjust the air until a trace of smoke appears on the filter paper after the system has been fired for 5-10 minutes or has reached steady-state conditions.

Next, measure the CO₂ or O₂ percent. You want the highest level that can be reasonably expected, so check to be sure that the burner is equipped with the correct combustion head, static plate and specified nozzle. Let’s assume you find 14.0% CO₂ at a trace of smoke. DO NOT LEAVE IT THERE! Adverse variable conditions will cause this level to deteriorate and deposit soot in the flue.

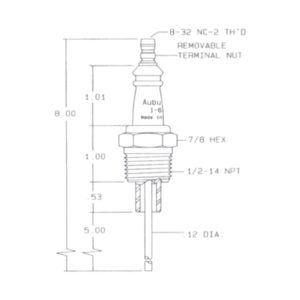

Add insurance air until you lower the CO₂ by one and one-half percent (increase oxygen by the same amount). Now, take a smoke reading. It should be zero. You have lost very little combustion efficiency, but more importantly, you have paid a very small premium to insure against soot-up. (See Figure 1.)

Cycle the burner. Does it light smoothly and shutdown quietly without rumble or pulsation? These symptoms could reveal improper electrode adjustments or air entrapped in the nozzle adapter. DO NOT LEAVE IT IN THIS CONDITION! Air compresses during operation and expands at shutdown, causing an after-squirt when the flame is gone. With no air from the blower, this usually means heavy smoke and carbon flashing off the refractory floor that can accumulate on the flue passageways. So cycle the burner until all evidence of after-squirt is gone. The constant expansion and contraction of the air bubble causes fragmentation with each cycle until it is passed through the nozzle. However, if the condition persists, there may be suction line leaks. Make necessary repairs before proceeding.

Make sure that there is sufficient fresh air available for combustion. Most codes require an opening to the outside equal to one square inch per 1000 BTU’s of input, or approximately one square foot per gallon/hour firing rate (140,000 BTU’s + 1000 = 140 square inches). See NFPA 54 National Fuel Gas Code Publication for specifics.

Suction Line Leaks

Whatever it takes, THE OIL MUST BE FREE OF AIR. This can be a tough problem, but it must be resolved. Try bleeding the pump through a clear tube. There must be no froth visible. There are various test kits available to enable you to look at the oil through clear tubing adapted to the supply line at the pump fitting. Air eliminators are on the market that have potential. Also, electronic sight glasses are being used with good success. At times, new tubing must be run to the tank or new fittings put on. Just make sure you get the air out before you leave.

Nozzle Selection

Probably, the most overlooked yet crucial item is the nozzle. While most of us would be delighted if one nozzle spray pattern and angle met all of our requirements, the tremendous variety of applications demand a multiplicity of nozzles.

Modern burners and heating appliances are carefully designed and tested for the highest efficiency possible. The selected nozzle is part of these specifications. Failing to use the correct nozzle can lead to many problems including: impingement of oil spray upon refractory surfaces, carbon or coke trees, delayed ignition or puff-backs, smoky flame tips, incompatible flame shapes and even loss of flame retention.

Remember, the burner type and chamber design dictate the nozzle selection. ALWAYS USE THE ONE SPECIFIED BY THE APPLIANCE MANUFACTURER. This will, of necessity, require having more than one style of nozzle in your inventory, but the results are worth it.

Conclusion

In summary, all of us in the industry must adapt our thinking to accommodate the realistic conditions that exist in our marketplace. These have changed dramatically in recent years. AFUE ratings, appliance redesign, lower input rates, lower flue gas temperatures, older chimney designs, advances in burner performance and increased pressures from alternate fuels mandate that we keep abreast of the impact that each change creates. We must upgrade our technical skills and understanding to meet these challenges.

Objectively, we feel that the vast majority of appliance soot-ups can be successfully prevented by methodically reviewing the COMPLETE installation beforehand and building in preventive measures. Foremost, is to follow the Manufacturer’s specifications implicitly regarding burner and nozzle selection, and then take all variables into account when making the final burner adjustments.

Those principles will get you started on the right foot. To stay there, you must follow up with a THOROUGH annual maintenance program that keeps the entire burner/appliance system clean and operating within the above prescribed levels. These methods are field-proven.